03 February 2023

Casolla Legno

20 years of partnership in the production of decks and 4-way pallets

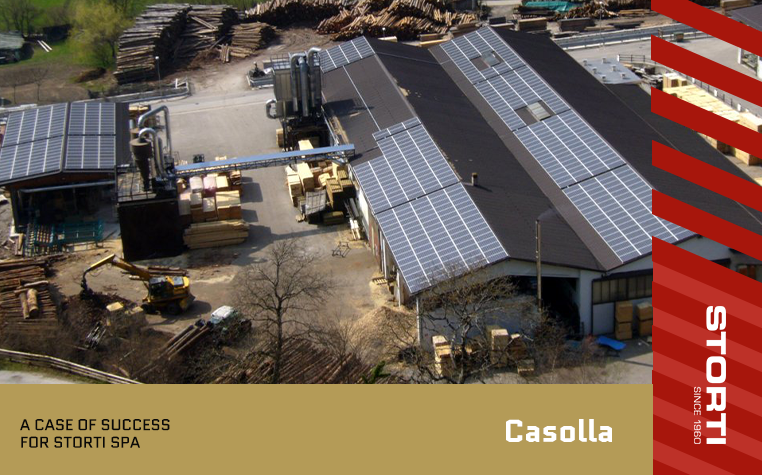

Casolla Legno Srl is an Italian company based in Trentino, in Val di Ledro, in the province of Trento. Specifically, it is "a leading artisan wood company specializing in the production of wooden pallets and packaging, PEFC- labeled natural poles and sawn timber for carpentry"t;

Founded in 1980 by Ivano Casolla and enlarged along with his brothers, the company adopts a modern and innovative approach designed to enhance the already strong connection with the land and wood. Ecological wood products are made with "just in time" production and delivery approach.

The sustainability of processes and products is so important, that native wood is processed in all its phases by the company and delivered to the customer as a finished and long-lasting product. The end result is an environmentally friendly zero miles product.

In order to maintain an innovative and sustainable approach, over time Casolla Legno has chosen to rely on Storti S.p.A. to supply several production lines.

What lines has Storti supplied?

Casolla Legno is primarily engaged in the production of wooden pallets and packaging. It works exclusively with quality wood and pays exceptional attention to the sustainability of products and processes, choosing a short and zero miles supply chain and using energy from renewable sources, in full respect of the Trentino region where it is located.

Casolla Legno Srl has been a customer of Storti S.p.A. since 1988. Its goal has always been to improve the efficiency of its machining, logistics and production processes. This is in addition to the aims of making production more flexible, according to the modern "just in time"; approach, and to keeping quality high. Already in possession of two nailing lines for the production of 2-way and 4-way fast-change pallets, Casolla Legno recently purchased a flexible fast-change nailing line from Storti for the production of decks and 4-way pallets.

This automated, efficient and flexible line will be used by Casolla, along

with the others already supplied, mainly for the production of:

- standard pallets

- oversized pallets

- 2-way pallets

- 4-way pallets

- perimeter pallets

- full deck pallets.

The machine made for Casolla Legno has other features that make it unique and particularly efficient for the customer';s needs: in addition to nailing, it has an automatic edge cutting system for both sides of the deck. This allows the customer to optimize the previous sawmill cutting system and achieve minimal waste with minimal use of variants and dimentions, all controlled by computer.

In addition, it has been equipped with accessories for more precise management and better monitoring of production and the Pall Pro 2 Software for drawing pallets.

Speed in format change

One of the areas in which Casolla Legno is most active is in the production of pallets with a wide variability of formats. This feature was taken into consideration when supplying nailing lines for pallets. What follows is what Storti S.p.A. did when designing and supplying the line for Casolla.

The production of pallets with different sizes is characterized by continuous format changes; as a result, these pallets differ from each other by a few centimeters in size, and generally only a few pieces (1 to 10) are produced for each size. Because of this extreme variability, it is essential to have, in addition to fast format change machines, very efficient software that allows to produce batches to be transferred from the ERP to the machines, with a minimum amount of time spent by the operator assigned to the machine. The solution provided by Storti has enabled Casolla to achieve these results.

The benefits obtained

The objectives of the line installation were to achieve high quality production with better changeover times. The pallet production and nailing lines were custom-designed in accordance with Casolla Legno's requirements: improved performance and a significant reduction in changeover times were achieved, while at the same time ensuring ease of use by operators.

So far, the partnership between Casolla and Storti has made it possible to achieve the goals set. In addition, the choice of Storti has also brought other benefits:

- Quantitative, with production of significant quantities;

- Qualitative, with greater accuracy of pallets and advantages of fast format changes;

- Possibility of using various wood qualities;

- Increased productivity and improved timber performance.